What Is Light Failure? Understanding the Basics

When we speak of light failure, we are speaking of any condition in which a light source is no longer functioning properly. This can mean lack of light emission at all or substantially reduced intensity or alternatively intermittent flashing. The reasons for light switch failure or LED light failure, especially, are associated with technical and environmental conditions. In industrial applications, Industrial Lighting Failure can cause major problems, which is why it’s crucial to know the fundamentals.

For instance, one of the characteristics of light failure is the damage of internal parts of a device due to mechanical stress or inadequate thermal management. This can cause problems such as early failure or even a total failure of the lighting system in accordance with industry standards. Similarly, the absence of quality checks during the installation process or problems with manufacturing the product can contribute. When it comes to the choice between incandescent bulbs and the newest LED technology, knowing about the light failure definition basics will define the best solutions.

In most cases, it is the trivial things like a loose connection in the wire or a difference in voltage levels. For instance, a flash from the naked bulb could mean even pulsations of currents, which can always be blamed on the malfunctioning switch or connection. Understanding these basics is useful in creating the foundation for dealing with failures in both residential and business applications.

Common Causes of Light Failure Across Lighting Systems

Light failure is a problem that occurs in all types of lighting, including incandescent, fluorescent, halogen, LED, and others. It is crucial to know the common causes in order to solve the problems and achieve stable performance. Below are the general reasons for light failure and their frequency of occurrence:

- Thermal Management Issues (High Frequency)

Heat is one of the main causes of lighting failures, particularly for the current LED systems. LEDs produce heat that must be managed properly lest it affects other parts of the LED such as LED chips or drivers. If not controlled, heat can lead to early failure or severe reduction in the efficiency of the device, contributing to a significant failure rate of failures, especially in poorly designed or installed fixtures.

- Electrical Issues (Frequent)

Another minor problem is voltage fluctuations, or voltage surges, meaning that the voltage either rises or drops momentarily. Fluctuating power supply or unstable electrical current disrupts the flow of electricity, causing strain on the lighting system that may cause flickering, dimming, or failure in the long run. These issues are worse in commercial or industrial installations because much more electrical power is used.

- Environmental Factors (Moderate Frequency)

Outdoor factors including moisture, humidity, vibration, or corrosion all have highly detrimental impacts to any luminous source. For example, water leakage in outdoor luminaires or exposure to corrosive conditions will affect internal wiring and destroy enclosures.

- Installation Errors (Frequent)

Inadequate installation is another major concealed reason for failure. In some cases, loose connections may occurs as well as physically incompatible components or inadequate insulation may lead to low performance or hazardous conditions. For instance, a loose connection as small as that may cause intermittent failures that are not easy to identify.

In any repair operations, one has to establish the cause of the breakdown so as to smother handle the problem. This is important because when diagnosing the root cause of the problem, one is assured of having the right solution to the problem. If these causes of light failure are well addressed, then the time taken for repair and replacement, cost of maintenance, and the number of replacements required will be greatly reduced.

Light Failure by Light Type: Incandescent, LED, CFL, and Halogen

Various lighting systems have their own failure modes associated with the design and operation of the system. Understanding these issues can help in troubleshooting and preventing light failures:

- Incandescent Bulbs: That is why incandescent bulbs actually just go bad over time: The filament simply burns out after being used for a long time. The filament can be damaged by voltage fluctuations or mechanical stress, for example, shaking or an impact.

- LED Lights: LEDs are very efficient and long-lived, but their failures are associated with heat, faulty drivers, or worn-out internal components, particularly in low-quality luminaires. Problems such as low brightness, blinking or complete black out are common due to inadequate heat dissipation, wiring problems or wrong dimmer switches.

- Compact Fluorescent Lamps (CFLs): One of the most frequent problems that CFLs experience is ballast problems, which may cause flickering or no lighting at all. Varying electrical currents, particularly in areas with unstable electricity supplies, also interfere with or even destroy the arc-tube – vital for CFLs.

- Halogen Bulbs: Halogen lights, which are bulbs that work at higher temperatures than other bulbs, are easily over heated. Any kind of skin oils or dirt on the surface of the bulb can cause hotspot and reduce the life of the bulb even more. Also, their electrical connections may be poorly made and may cause them to perform erratically or burn out.

Common Light Failures by Type

| Lighting Type | Common Issues | Contributing Factors | Average Lifespan |

| Incandescent Bulbs | Filament burnout, mechanical failure | Prolonged use, voltage surges, mechanical stress | 750–1,200 hours |

| LED Lights | Overheating, driver failure, inconsistent brightness | Poor heat management, low-quality components, incompatible dimmers | 25,000–50,000 hours |

| CFL Bulbs | Ballast failure, arc-tube degradation | Power fluctuations, humid environments | 8,000–10,000 hours |

| Halogen Bulbs | Overheating, surface contamination, loose connections | High heat, dirt buildup, improper handling | 2,000–4,000 hours |

Various problems are inherent to all kinds of lights, though using high-quality materials, installing lights correctly, and applying components adapted to certain settings can help avoid them.

Environmental Factors That Contribute to Light Failure

Lack of light is not always attributed to the fixture in question or the luminaire itself. More often than not, the context is of significant importance, and any mismatch can arise. Moisture levels, temperature variations, vibration, and other pollutants are among the things that may have major influence on the performance and durability of the installed lighting systems. Let’s look at how these factors impact different settings:

- Retail Spaces: In shopping malls, dust and grease build up on the surface of the luminaires and reduce the light output progressively especially in the food court or kitchen. These problems are worse in poorly ventilated areas, and hence, cleaning is required frequently.

- Industrial Environments: Machinery vibrations and high intensity operations cause electrical connections in factories to become loose. Temperature changes in industrial buildings also put pressure on materials, which can cause early failure of LEDs or halogens.

- Outdoor Areas: Outdoor lighting is a critical area where moisture exposure is a major concern. When water gets into fixtures, it can corrode the internal parts of the fixture leading to electrical shorts and fixture failure. Another danger is fluctuation of temperature, both high and low.

- Residential Spaces: In homes, power supply is usually inconsistent especially in old structures. Fluctuations in voltage can cause premature failure of lights including LED and CFL lights.

Summary: Environmental Factors by Application

| Application | Environmental Factor | Impact on Lighting | Preventive Measures |

| Retail Spaces | Dust, grease buildup | Reduced light output and fixture degradation | Routine cleaning and proper ventilation |

| Industrial Areas | Vibrations, temperature fluctuations | Loose connections, stress on sensitive components | Use vibration-resistant fixtures, temperature-stable materials |

| Outdoor Settings | Moisture, extreme heat/cold | Corrosion, electrical shorts, thermal stress | Weatherproof fixtures, sealed casings |

| Residential Homes | Power supply irregularities | Reduced lifespan, intermittent failures | Use surge protectors, stable voltage sources |

These risks can be significantly reduced and the life of the lighting systems increased through proper maintenance, using high quality materials and fixtures appropriate to the environment.

How to Diagnose and Fix Light Failure: Step-by-Step Solutions

In light failure, the first thing that you need to do is to find out what has gone wrong. This might seem rather basic advice but it is crucial to determine whether it’s the fault of the light switch or if the issues lies with a connection or the fixture. First of all, switch off the power supply—this is the first rule when it comes to electrical repairs and electrical work.

- Inspect the Bulb or Fixture: Take out the bulb and inspect for such obvious signs of problems such as cracks, oxidisation or burn out components. If it’s an LED light fixture, look at the LED chip and the parts around it to check for deterioration. For instance, the traditional incandescent bulbs should be replaced if the filament is damaged.

- Check the Wiring and Connections: One of the problems is that the wires are not connected properly. Be very selective with regards to the coupling and make sure that the current path is unimpeded. Difficulties here may result in flickering or, occasionally, the complete failure of the lighting system.

- Test the Dimmer or Light Switch: A faulty dimmer switch or a light switch can imitate more serious problems. Replace it with another model of the same type to check if the issue will be solved. For LED lighting solutions, not all dimmers are compatible with advanced LED drivers; therefore, check compatibility.

- Evaluate the Power Supply: Fluctuations in voltage are often a cause of light failure that is not given much attention. Confirm the incoming voltage using a multimeter, to make sure that your particular type of lighting fixture can operating safely on it. Defects in the power supply can cause the degradation of components.

- Replace or Repair Components: In cases where the problems are more chronic in the LED lighting systems, then you may require to replace the led driver or even re-insulate the wires that have been affected. For highly rated temperature, it may be useful to look for foreign obstacles which may obstruct ventilation or increase the overall air movement around your fixture.

If you follow this detailed, systematic approach, you may be able to fix the problem on your own most of the time. However, if all the above methods do not work, then the only solution is to call an electrician.

How to Prevent Future Light Failures

Preventing light failures is not a very complex affair and it entails following a number of fundamental guidelines. The tips provided are general and can be used in any type of lighting and are useful to the homeowners, business people and the industrial users.

- Regular Inspections: Check for fixture looseness in the connections and possible corrosion and other possibilities.

- Cleaning: The surface layer of dust and dirt can accumulate and, in addition, will gradually reduce the luminous flux. Cleaning of bulbs, lenses, and fixture daily, weekly or fortnight depending on the type of bulbs installed.

- Proper Installation: Installation of fixtures has to be done by experts and all parts have to be installed correctly. This is because loose wiring or mismatched components are likely to cause early failure of the circuit.

- Ventilation: Lack of heat control especially in sealed luminaires is very unbeneficial to lighting systems in the long run. Fixtures must be cool enough to avoid heat build up, therefore fixtures should be well ventilated.

LED Lighting: Expert Advice on Enhancing LED Efficiency

Over the past few years, LED lighting has emerged as the most popular lighting solution among homeowners, businesses, and industries alike—and for a good reason. LEDs (Light Emitting Diodes) are not only energy savers, using as much as 85% less electricity than incandescent or halogen bulbs, but they also have a very long life expectancy of 50,000 hours or more. Depending on exact specifications, this can be equivalent to years—if not decades—of problem-free use with relatively slight attention to maintenance. Moreover, LEDs have many more advantages compared to incandescent lamps: lower heat emission, greater latitude when it comes to the design, and environmental friendliness because these lamps contain no hazardous elements like mercury. That is why, the use of LED lighting is a wise decision which, at the same time, is oriented on the future perspective.

But if you’re going to get the most out of LED lighting, it has to be used and maintained properly. While LEDs are generally durable fixtures, let’s take a closer look at problems such as improper installation, excessive heat, or incompatible components that can affect a fixture’s functionality or shorten its life.

Tips for using LEDs:

Prioritize High-Quality Components

It is therefore important to understand that not all LEDs are the same. One must invest in well designed and premium LED lights. Conventional or low-quality LEDs have ingredients that make them prone to earlier failure through overheating, low efficiency and unstable setting. If you go for the high end products then you may end up paying a slightly higher price but the frequent replacements plus your electricity bills will be far cheaper in the long-run.

Ensure Proper Heat Management

Heat is the invisible killer of LED efficiency. While comparing with the incandescent bulbs, the LEDs produce very little heat but they do produce some heat inside them. Heat or inadequate air flow is a major enemy of LED chips as it may shorten LED lifespan or even decrease its brightness. It is also important to always check that the fixtures you use provide enough ventilation.

Select the Right Characteristics of the Drivers and Dimmers

LED continues to function optimally if it receives a good supply of power. Current controlling drivers are important to avoid problems such as flickering or overloading of the electrical current and effectively managing the current flow to the LEDs. It is always recommended to use high quality LED drivers that can meet the wattage of the fixtures. Likewise, not all dimmer switches are compatible with LED lights or bulbs that are used in homes and other buildings. Using different types of dimmers is also fatal to the lightings since they will have a short life span, they will produce irregular outputs, or fail completely.

Install with Care

Installation is as important as the quality of the product that is being installed. Soldering problems, bad connections or alignment problems can cause performance problems and dangerous situations. LED system installation is not only about safety but also about performance when done correctly.

Check on Certifications and Standards

When choosing LED products, look for CE, RoHS or ISO9001 marks that prove that the product meets safety and quality requirements. Certified products are developed to undergo various tests, and therefore they are safer and more reliable than other products.

Using the measures above you are able to optimize your LED lighting system to its full potential. LEDs, if selected and managed properly, are not only a lighting system, but a long-term investment.

At WOSEN, we are interested in creating LED fixtures that have long life spans. Our lights are made of high quality material like ADC12 aluminum and top grade lamp beads. In terms of durability standards, each and every product being manufactured goes through well over 50 testing procedures.

Besides, WOSEN products are CE, RoHS, SAA, ISO9001 certified to ensure that they meet the international quality standards. For the distributors, contractors or project managers who do not want to be concerned with light failures, WOSEN is a brand that provides both reliability and performance. Our products shield you from after-sales issues and let you offer dependable lighting solutions.

Final Thoughts: Identifying and Solving Light Failure Effectively

However, such a problem as light failure seems negligible at best at the beginning, though inaction and its cause generate worse consequences, from poor productivity to equipment failure or even safety threats. It doesn’t matter if you have flickering bulb, LED lighting inconsistency, or complete failure, early identification of the problem is much simpler.

Such a method can be applied to solve simple problems like resetting loose wire connections, and more complicated problems related to led driver or an electrical connection. The differences between different types of lighting such as LED lights, incandescent bulbs or CFLs also helps you to diagnose and solve failures.

Last but not the least you want to avoid having your lighting system clothes up with constant malfunctions and then the use of high quality fixtures will help in maintaining the lighting system for a long time. They will enable you to remain overly specific on your lighting setup while at the same time making sure that it meets all its potential in terms of energy and efficiency. For no doubt, good and effective lighting requirements are an important parameter that should be installed for accomplishing the attached tasks and objectives not only in the residential building but also among the industrial ones.

Related Products:

- All

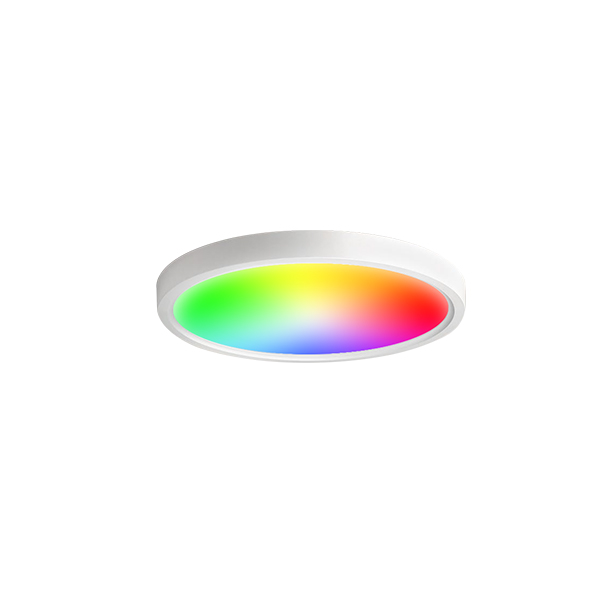

- LED Panel Lights

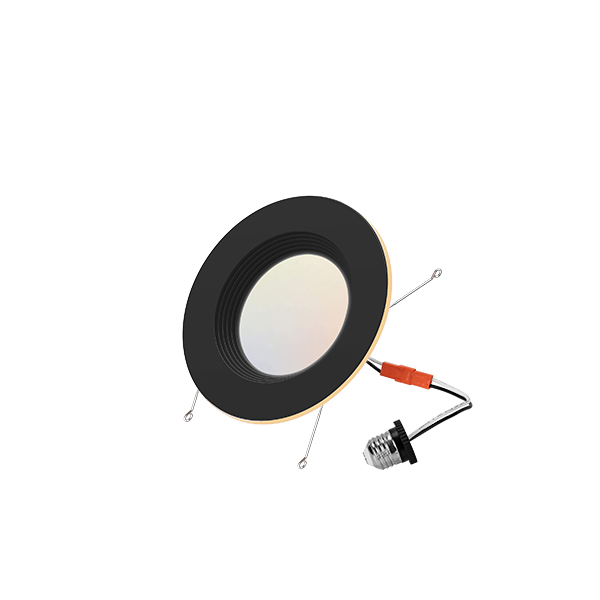

- LED Recessed Lights